In today’s manufacturing sector, businesses are under constant pressure to reduce waste, lower costs, and improve operational efficiency. One solution that stands out is custom extruded plastic in India, where industries rely on tailored profiles and parts designed for bulk production. By adapting extrusion to specific needs, companies can save material, reduce errors, and create sustainable supply chains.

What Are Custom Plastic Extrusions?

Custom plastic extrusion is a manufacturing process where raw plastic is melted and shaped into continuous profiles. These profiles can be rigid or flexible, depending on the application. Unlike generic materials, custom extrusions are designed to match exact dimensions and functions, which makes them more efficient in industrial use.

Custom plastic extrusions are specially manufactured plastic profiles made through extrusion to meet precise industrial requirements, reducing waste and improving cost efficiency.

Why Waste Control Matters in Manufacturing

Waste in production is not just about material loss it increases energy usage, storage costs, and disposal needs. For companies working at scale, even a small inefficiency can lead to significant financial loss over time.

Key issues with traditional methods include:

- Excess material cutting

- Inconsistent dimensions

- Higher rejection rates during quality checks

By using custom extrusion profiles, businesses can prevent these challenges right at the source.

How Custom Extrusions Reduce Waste

1. Exact Fit Production

Custom extrusion ensures that each plastic profile is manufactured to the required size and shape. This reduces the need for trimming, reshaping, or discarding material.

2. Streamlined Processes

When parts are pre-designed to fit assembly lines, production moves faster with fewer adjustments. This cuts down both labour waste and machine downtime.

3. Bulk Supply Advantage

Large-scale manufacturing in India allows for bulk orders of extrusion profiles with consistent quality. This reduces variations and prevents costly rework.

4. Recyclable Materials

Many plastic profiles are made with recyclable polymers. This means offcuts can be reused, making the process more sustainable.

Efficiency Gains Beyond Material Savings

Controlling waste is only one part of the story. Custom extrusion also improves efficiency across the entire supply chain.

Better Inventory Planning

When every piece is consistent, companies can predict stock usage more accurately, avoiding over-purchasing or under-stocking.

Faster Time to Market

Since profiles come ready for assembly, businesses can cut production steps and deliver products quicker.

Lower Transport Costs

Lighter and more compact designs reduce shipping weight and volume, bringing down logistics costs.

Industries Benefiting from Custom Extrusions

Custom extruded plastic profiles are not limited to one sector. They serve a wide range of industries, including:

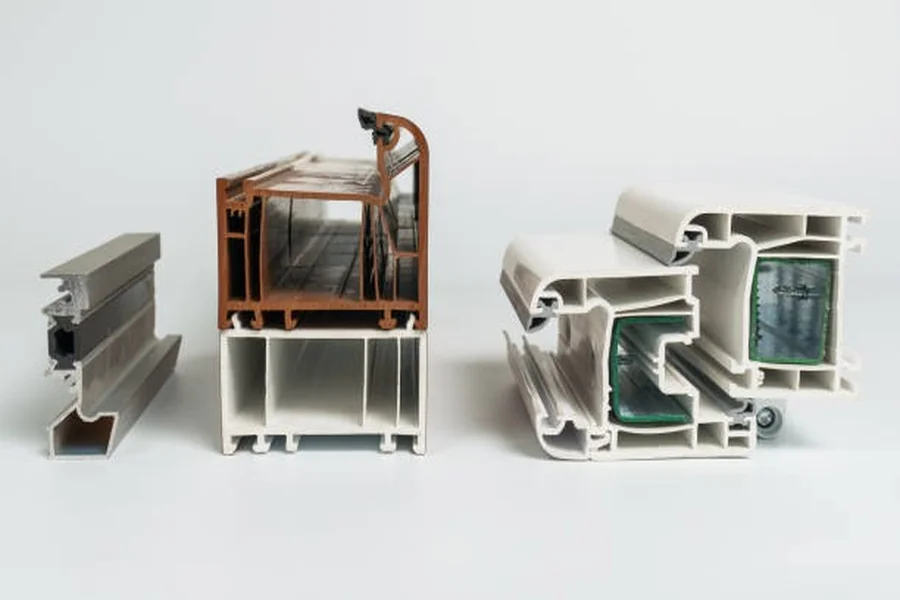

- Construction: Window seals, PVC trims, and structural profiles

- Automotive: Lightweight panels, protective strips, and cable covers

- Electronics: Insulating profiles and wire management channels

- Retail & Interiors: Display stands, shelving systems, and rolling shutter PVC

- Packaging: Strong yet lightweight profiles that minimise material use

Example: Reducing Waste in Large-Scale Projects

Consider a construction firm working on commercial housing. Instead of cutting standard PVC profiles on-site, they can use custom extrusions designed to exact window frame sizes. This prevents offcut waste, lowers costs, and reduces project timelines.

This approach is also relevant globally. Many businesses are looking at reducing waste and cost overruns with advanced extrusion solutions in the USA, which reflects how efficiency-driven practices can benefit companies regardless of location.

Sustainability and Environmental Impact

With industries facing stricter sustainability regulations, custom extrusions are an effective way to align with eco-friendly goals.

- Less Scrap: Accurate production means less discarded material.

- Energy Savings: Machines run efficiently without repeated adjustments.

- Recyclability: Thermoplastics like PVC, polystyrene, and polyethylene can often be recycled.

This balance of economic savings and environmental responsibility makes extrusion highly relevant for modern manufacturing.

Common Challenges and How to Overcome Them

While extrusion offers benefits, businesses may face hurdles:

- Design Complexity: Some profiles require advanced moulds.

Solution: Work with a manufacturer that supports design consultation.

- Material Selection: Choosing the right polymer affects durability.

Solution: Match the plastic type to end-use conditions (heat, impact, weather).

- Volume Requirements: Small runs can be costly.

Solution: Plan for bulk production to get consistent pricing.

By partnering with reliable suppliers such as M3 Extrusion, companies can overcome these challenges with confidence.

FAQs

1. What is the main advantage of using custom extruded plastic in India?

The main advantage is efficiency. Companies receive profiles designed exactly to their needs, which reduces material waste, speeds up production, and lowers overall costs.

2. How does extrusion improve waste control compared to traditional cutting methods?

Traditional cutting generates offcuts and errors, while extrusion produces continuous profiles in the required size, eliminating unnecessary scrap and improving consistency.

3. Can custom extrusions support bulk manufacturing?

Yes. Extrusion is ideal for bulk orders because it delivers consistent, repeatable profiles at scale, making it suitable for industries that need reliable supply chains.

4. Are custom plastic profiles recyclable?

Many extruded profiles are made from recyclable plastics such as PVC, polyethylene, and polystyrene. This allows manufacturers to reuse materials and reduce environmental impact.

5. Which industries benefit most from extrusion in India?

Construction, automotive, electronics, and retail industries use extrusion widely. It supports cost-efficient, high-quality components that fit seamlessly into larger systems.

Conclusion

Custom plastic extrusions are transforming the way industries manage production. By controlling waste, improving efficiency, and supporting bulk manufacturing, they deliver both financial and environmental benefits. Companies that adopt this approach position themselves strongly in competitive markets, where reliability and cost control matter most.